Are you ready for this 3D technology? Would you buy a handgun made with it? Are there risks for our society? Should the technology be freely available to everyone? If so, what factors are involved and how do we or can we keep the bad guys/gals away from the process, software, printing, and criminal use of the equipment and end products? Is it even possible to control the “tools” produced from this technology and the equipment and process used to make them? Many complex issues, variables, and concerns for a well-intentioned technology for our future. Solid Concepts (SC), a multi-state manufacturer headquartered in Austin, TX, announced that they built the world’s first 3D-printed metal gun in November of 2013. Just last week they followed-up by introducing the first 3D-printed metal M1911 in .45 caliber that requires no tooling. A few limited editions of the handgun are offered last week at a worldly-price of $11,900. “This is a chance to own a piece of history,” says Vice President of Marketing Scott McGowan. What are the pros, cons, and considerations of the process and its uses?

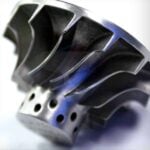

3D printing services have become increasingly popular in recent years as an easy, cost effective solution to create real parts from 3D CAD data. “3D printing” is a term used to describe additive manufacturing technologies that produce custom parts by accurately “printing” layer upon layer of plastic or metal material until a 3D form is created. The handguns are made of a nickel-chromium allow and stainless steel powdered-metals that are fused together by lasers in layers with added support structures to create very strong and durable guns. They call the process Direct Metal Laser Sintering (DMLS.) All parts, including the barrel, its rifling, and the bore’s lands and grooves are 3D printed and then made in a very short time by this unique process. This week I contacted Brianna Gillett in the SC Marketing Department and she gave me a product update and permission to show the photos in this article. The prototype handgun fired 2,000 rounds without malfunctioning once and worked flawlessly, according to SC. Each assembled pistol will undergo 100 rounds of test firing before sale. The gun is a classic 1911 design and SC says it functions beautifully. Of course, accuracy is a concern of shooters. An SC engineer said “Our resident gun expert has fired 50 successful rounds and hit a few bull’s eyes at over 30 yards. The gun is composed of 30+ 3D Printed components with 17-4 Stainless Steel and Inconel 625 materials. We completed it with a Selective Laser Sintered (SLS) 3D-Printed hand grip.” The 1911 is functioning very well, but the real benefits are in the metal sintering process itself which includes fast replacement components should anything function at less than optimal levels by simply re-printing a component with proper design corrections. The 1911 3D-Printed metal gun was manufactured 40 micron layer by layer with 3D printing and was not machined via conventional CNC methods.

Here are the handgun’s specifications.

1911 3D-Printed Metal Gun Technical Specifications:

Weight: 2.25 pounds empty, no magazine

Width: 1.3 inches

Trigger Pull: 5 pounds

Sight Radius: 6.4 inches

Sights: Standard GI with square notch rear

Twist: 1:15.8; 6=Lands 6=Grooves

SC has provided custom manufacturing solutions via additive manufacturing, rapid prototyping, CNC machining, cast urethanes, injection molding and tooling since 1991. The processes are not new and they use their engineering expertise from multiple fields to bring various new 3D-printed metal and polymer products for the aerospace, medical, consumer products, and other industries.

RAF Tornado fighter jets have flown with parts made using 3D-printing technology, according to defense company BAE Systems. It is hoped the technology could cut the RAF’s maintenance and service bill by over £1.2m over the next four years. BAE engineers are producing the parts for four squadrons of Tornado GR4 aircraft at RAF Marham in Norfolk, with some parts costing less than £100. Mike Murray, head of airframe integration at BAE Systems, said: “You are suddenly not fixed in terms of where you have to manufacture these things. You can manufacture the products at whatever base you want, providing you can get a machine there, which means you can also start to support other platforms such as ships and aircraft carriers.

With such a wide range of materials available, 3D-printed parts can be used for everything from a cosmetic architectural model to a functional racecar component. The 3D-printed products have several advantages. Nearly every industry has utilized 3D-printing technologies due to their quick turnaround time and ability to produce stunning models to exact specifications that stay within budget. 3D printed parts can be expertly finished to closely resemble your mass produced part or left unfinished for a fast representation of your design. Some say they could be used on the battlefield to quickly make extra ammo and spare guns and parts quickly at a very decent price. The technology exists and even with a moderately-priced printer and software, metal products, guns, and parts could be economically made. Of course, this remains to be seen.

There are pros and cons to consider with this 3D printing technology. In September, 2013, the U.S. space agency NASA announced that it is planning to launch a 3D printer into space in 2014 for the first time to help astronauts manufacture spare parts and tools in zero gravity. It is thought it could help reduce the costs of future missions. A worthwhile space exploration use.

Medical researchers in Australia have used this technology to create artificial arteries and skin and are planning to look at the creation of an artificial liver. Another worthwhile medical use.

Of course, anti-gun campaigners have already criticized the metal gun project and the 3D-printing of guns and parts. One idea based on the 3D-printing of metal handguns is as the printers and software become less expensive, instead of buying goods from shops, consumers will instead be able to download designs and print out the products they want at home. So, theoretically you could print and layer your own 3D metal guns at home. If you have 12 shooters in your family, you could print out 12 guns. Wow, what a concept. Naturally, there are inherent pros and cons, as well as many risks involved. What if a criminal intent on evil was able to print several guns and use them illegally and hurt others? Also, there could be a broader risk to national security, airport security, etc. A lot of considerations and challenges, with most not unique to 3D printing.

For example, a young law student in Austin, TX recently created a 3D plastic gun, according to the BBC News. The gun was assembled from separate printed components made from ABS plastic. Only the firing pin was made from metal. The gun was made on a 3D printer that cost about $8,000 from the online auction site eBay. To make the gun, he received a manufacturing and seller’s license from the US Bureau of Alcohol, Tobacco, Firearms and Explosives (ATFE). The ATFE, told BBC News that the 3D-printed gun, as long as it was not a National Firearms Act weapon (an automatic gun, for example), was legal in the U.S. So I suppose a person can manufacture a firearm for their own use. But, if they engage in the business of manufacturing to sell a gun, they need a license. However, I am not sure about the legality of this and this needs to be researched with the help of legal counsel.

Sadly, there is evil in our world. 3D printing technology has already been used by some criminal organizations to create card readers (“skimmers”) that are inserted into bank machines. In view of the ongoing gun debate in the wake of the shootings at Sandy HookElementary School in Newtown, Connecticut and other tragedies, some are already calling for the ban of 3D-printed guns under the Undetectable Firearms Act.

What are your thoughts about the 3D printing of guns?

What about the 3D-printing process for other products? Other products include football and firefighter helmets, medical and surgical implants, all kinds of technical parts in metal and polymer for appliances, machines, electronics, computers, aerospace, etc. Here are some product examples in prototype form:

To learn more about the world’s first 3D-Printed metal gun, visit the Solid Concepts website.

Continued success!