KYDEX was the invented by the Rohm and Haas Company, which was a materials manufacturer that worked in the aircraft interior industry. In the later part of 1960’s, industries realized that KYEDX thermoplastic sheets can be made into various shapes. This is achieved with the application of heat and molding the material around forms.

Right before the turn of the 21st century, in 1997, KYDEX, LLC was born. The term “KYDEX” has become the catchall generic name for plastic holsters. An interesting fact is that some companies sell what they call “KYDEX holsters”, which aren’t actually made with KYDEX plastics. And even if they are genuine KYDEX, not all holsters made from the material are created equal.

There are many shades of KYDEX

The same way leather is graded, there are also different grades of KYDEX. KYDEX currently manufactures over 40 different types of thermoplastic sheets, each with its own properties and cost. Some KYDEX comes in low-cost, budget plastics made from re-grind/recycled grades of sheet. This results in lower-cost products with lower performance standards than higher-cost higher-grade thermoplastics.

There are three factors which affect KYDEX sheets’ grade: thickness, grain, and ability to withstand temperature. Two types of KYDEX sheets that are the most popular with companies making gun holsters and knife sheaths are KYDEX T and KYDEX 100. KYDEX 100 is known a superior material for thermoforming. It is incredibly tough and durable, and offers excellent formability, rigidity, break and chemical and high temperature resistance.

KYDEX holsters are not all the same

Genuine KYDEX-brand plastic holsters are not made by means of injection molding. The reason for that is because KYDEX is engineered from pure polymers; their extruded sheets don’t contain blended stiffeners. KYDEX will last longer than cheaper plastics and is unlikely to damage your firearm, no matter how many times you slide the gun in and out of the holster. In order to create a KYDEX holster, manufactures heat a sheet of plastic and mold it around a form at point point they cut off the excess material and polish the finished holster. Creating a KYDEX holster is most assuredly a labor-intensive process that requires considerable expertise and strict quality control, and precise temperature and it must also be cooled properly.

KYDEX and its effects on gun wear

Holsters can cause wear and tear to the finish of your firearm. As a result, it’s the main issue that owners of KYDEX holsters have. In order to minimize this, holsters made of KYDEX must be created to follow the precise shape and form of the weapon inside it. Proper pressure must be applied on the specific areas of the firearm, and nothing more. When the weapon is matched and shaped to the holster correctly, quality KYDEX holsters will rarely present finish wear.

In closing…

If you’re willing to spend your money on a KYDEX holster you need to ask some basic questions such as what type of thermoplastic material is being used. Like a leather holster, a quality KYDEX holster is a much like any other hand-crafted product, and as such is one that is apparent in both performance and in its price point.

Where to Buy One

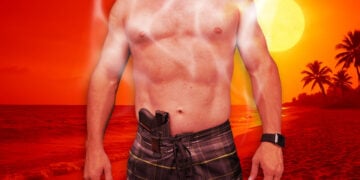

If you’re in the market for a new kydex holster, consider visiting Concealment Express’ online store. They have a large selection of high-grade, high-quality concealed carry IWB holsters, handmade in the USA, and offer free shipping on orders over $50.